PLASTIC INJECTION

THERMAL GATE HOT RUNNER SYSTEM

Great performance on the plastic injection process.

Fast, safe and with good performance on the injection. Recommended to parts of different sizes and applications.

More Information

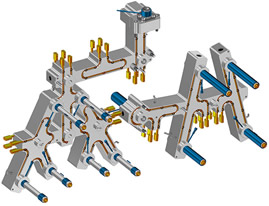

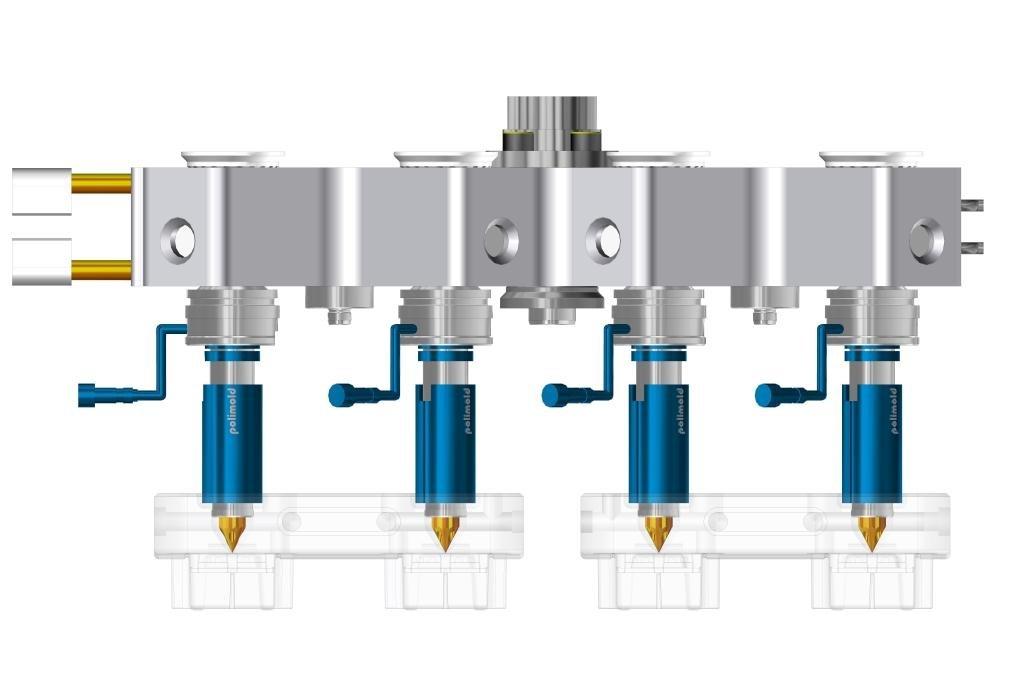

The Thermal Gate Hot Runner System is made of a Fully balanced manifold, nozzles, set up with tips and electrical box.

We have a diverse line of standard components to facilitate the manufacturing of the tool. We also develop special items according to your product’s needs.

Main advantages Conventional Hot Runner System:

- Less raw material, free of tensions and thermally homogeneous.

- Less pressure on the plastic injection, resulting on more precision.

- Easy processing on the injection of materials.

- Faster and more precise cycles.

- Versatile and flexible on product’s color change.

Polimold has various hot SPRUES dimensions for the APPLICATION according to the needs of the product. Please get to know the available series on the market:

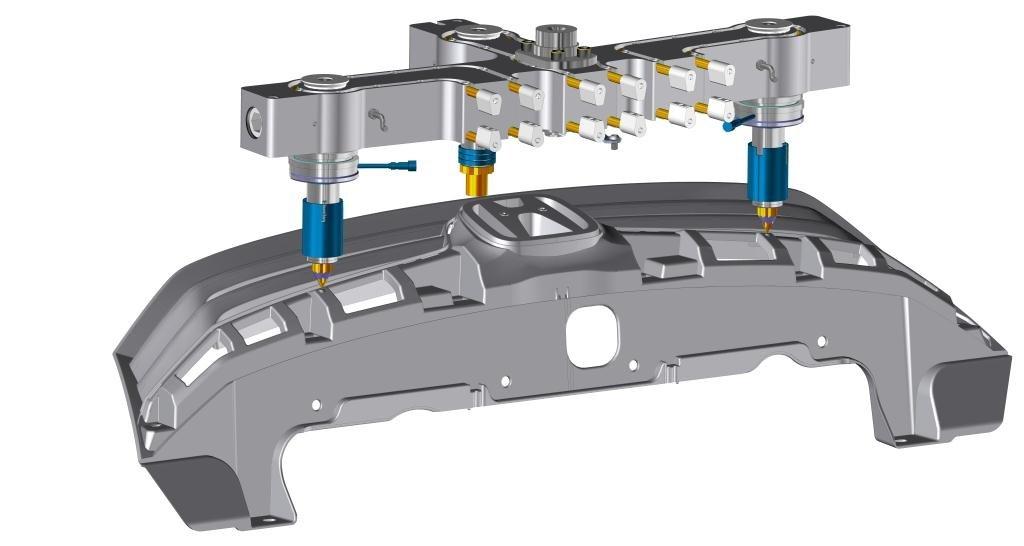

The Polimold Hot Runner System is recommended to plastic injections in a large numbers of industries, such as: automotive, packing, cosmetics, electronic devices, toys, construction, among others. Please check below some examples of the application of Standard Hot Runner System.

Gallery

Polimold is fueled by the challenge of creating products that exceed the expectations of clients! Check a few of our cases using the Standard Hot Runner System.

-

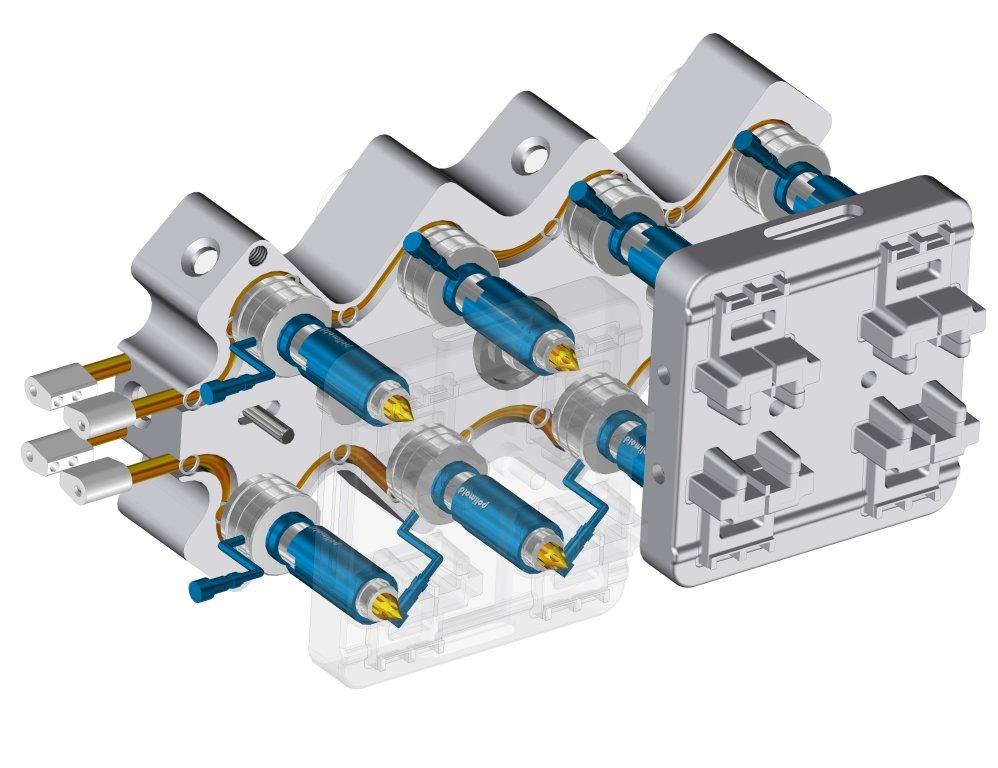

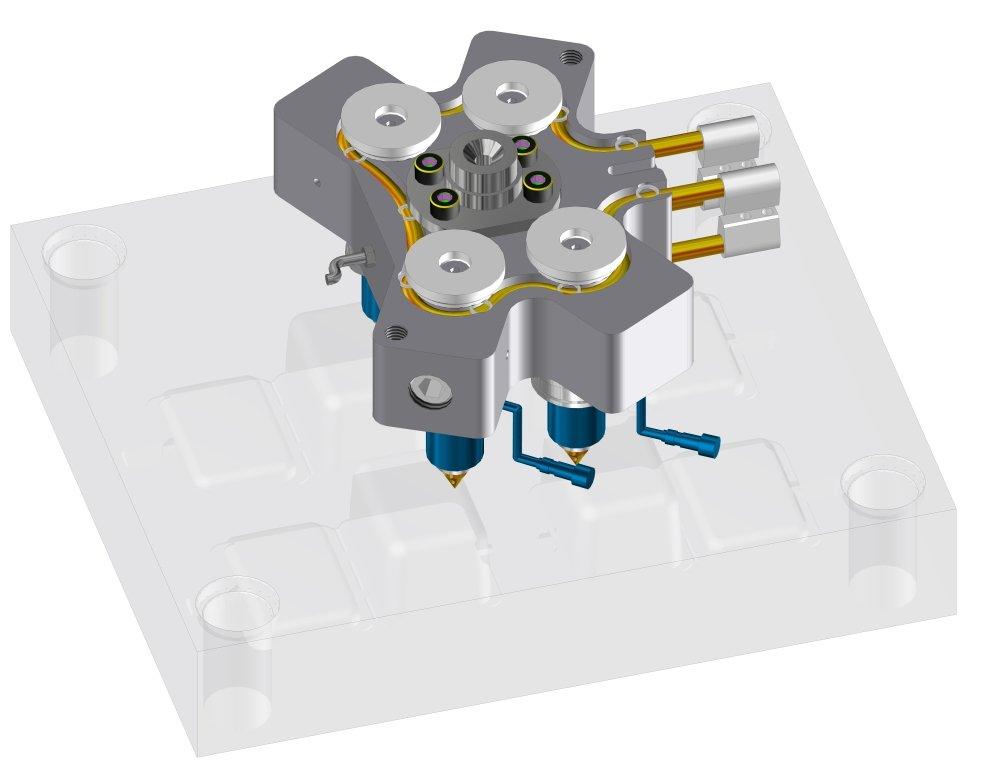

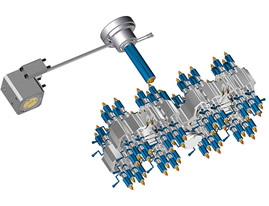

Bi Injection +

Polimold Solution:The client’s request was to inject parts with different materials on the same mold.

We developed a system with two different manifolds, one with a lateral input for the injection of TPE and the other input centered for the injection of material PA 6.

-

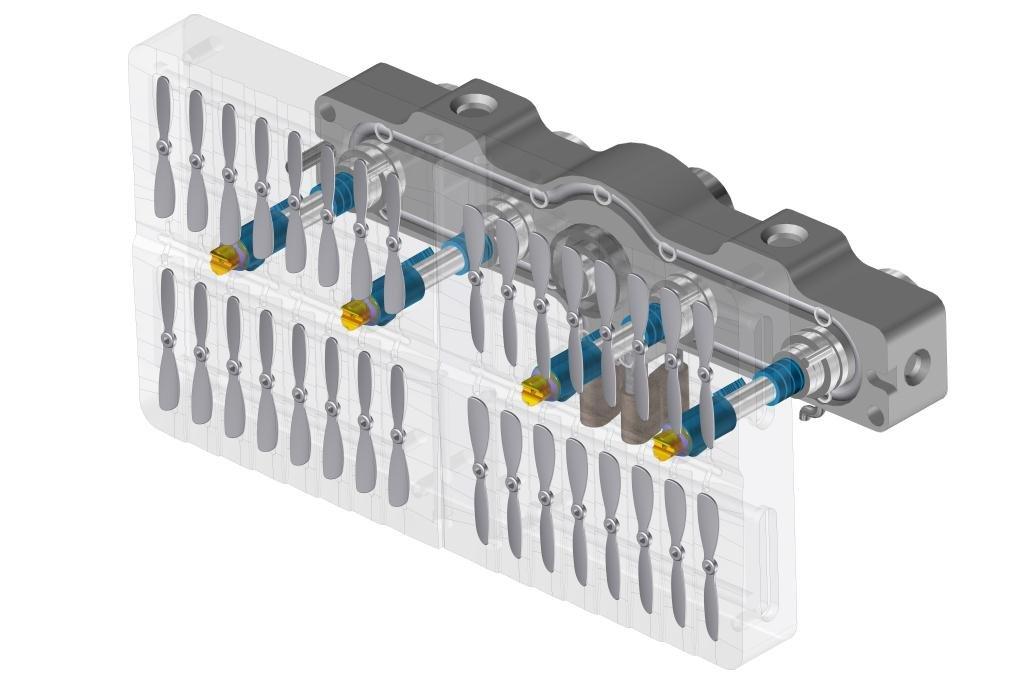

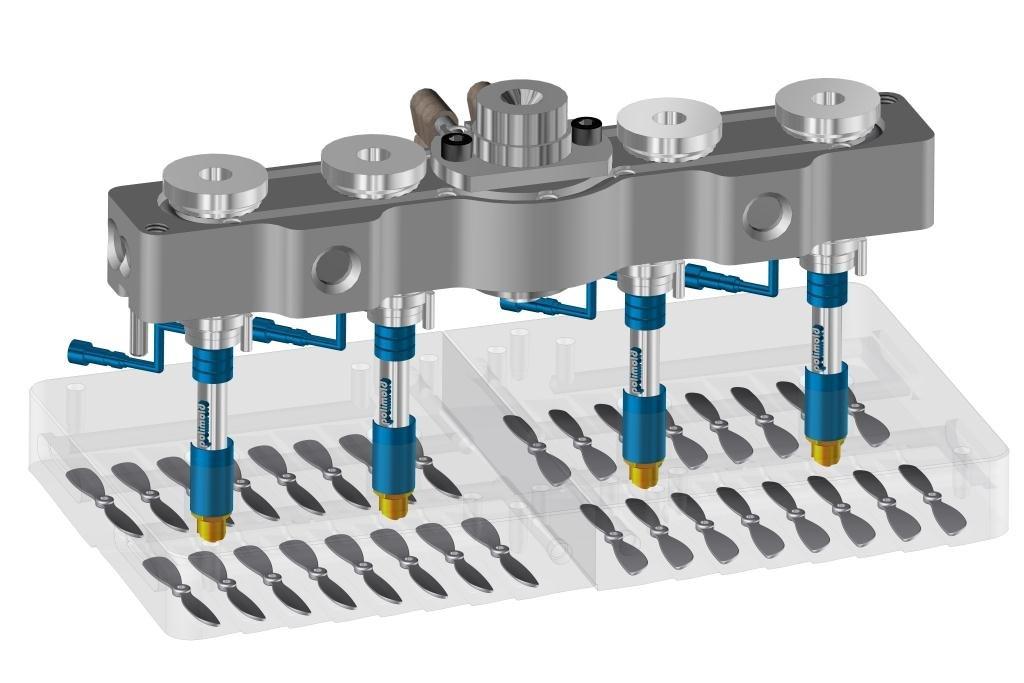

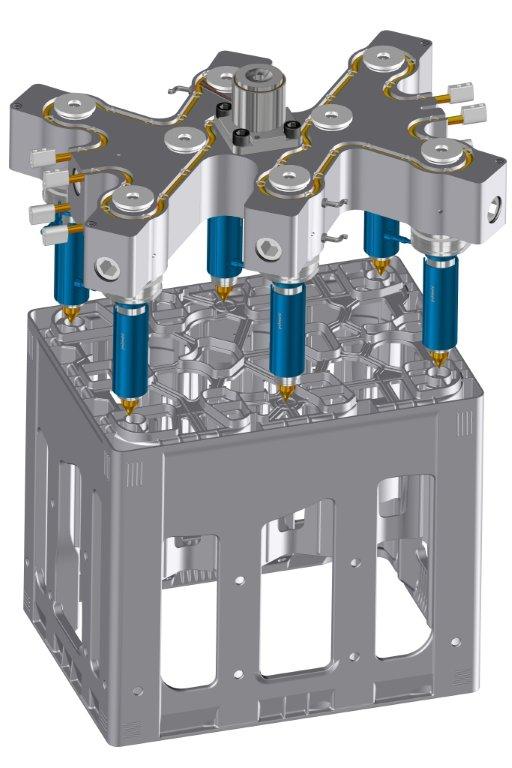

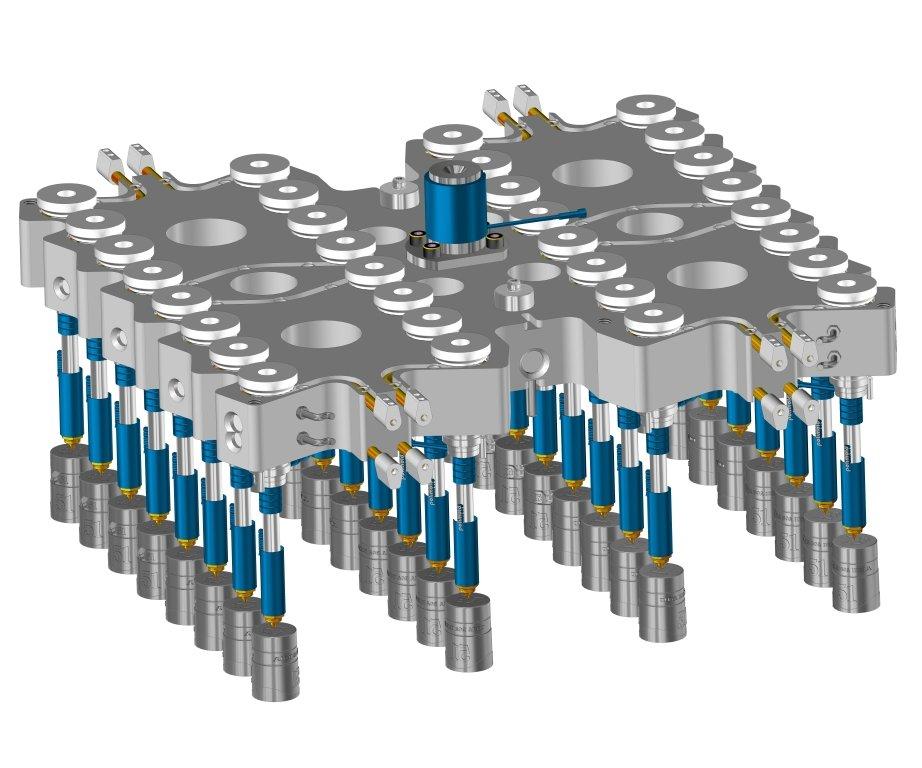

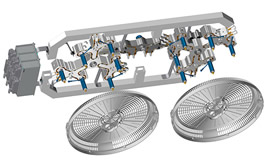

Stack Mold +

Name of the part: Spacer

Material: PE AD

Weight: 10 g

Cavities: 64 (32 + 32)

Injection Points: 32 + 32

Injection: Conventional Hot Runner System – Stack Mold

Serie: 200

Line: Policosmetic

Polimold Solution: In this case, we had to increase the productivity of the mold using a single injection tool on a small-sized machine.

We developed a conventional stack mold injection system to produce parts on both sides of the mold.

The great challenge of this project was on the closing section of the mold, where we predicted the material could purge, causing trouble on the mold closing. we choose a valve gate sprue bushing with a valve gate feeder bushing, without changing the main idea of the project.

-

Injection with Surlyn+

Name of the part: Perfume Cap

Material: Surlyn

Weight: 22 g

Cavities: 8

Injection Points: 4

Injection: Standard Hot Runner System – “Sobre Canal” Model

Serie: 200

Line: Polimax

Polimold Solution: For the injection of surlyn, where the injection pressure is higher than compared with other materials, the polimold engineering developed an injection system where the nozzles are threaded in the manifold, preventing possible leaks of raw material.

-

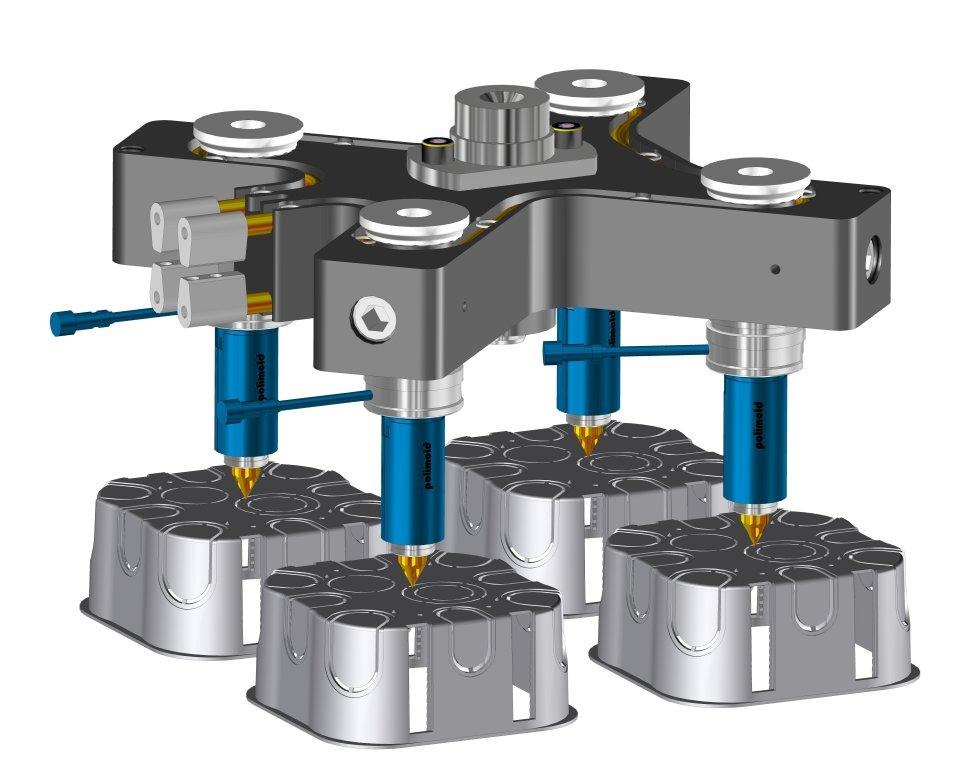

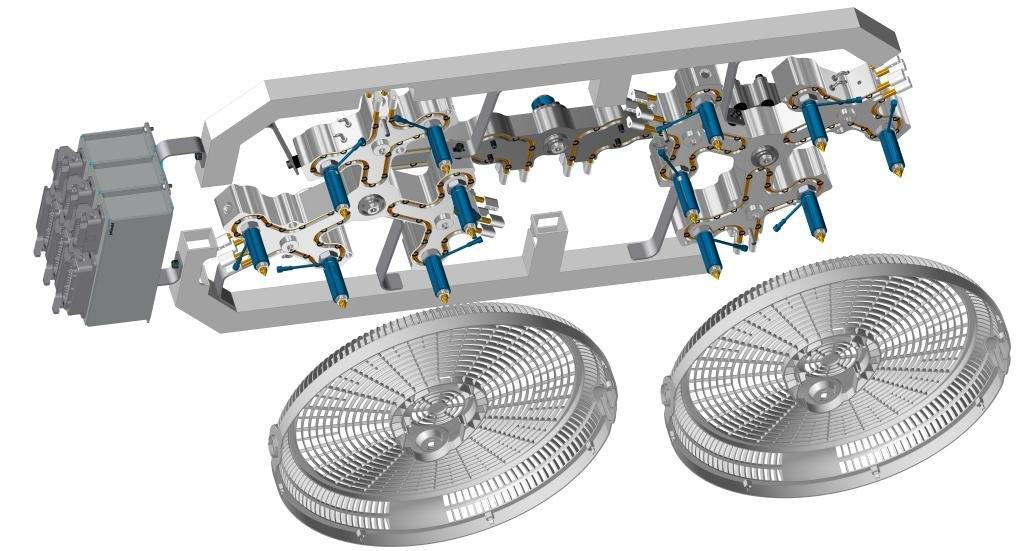

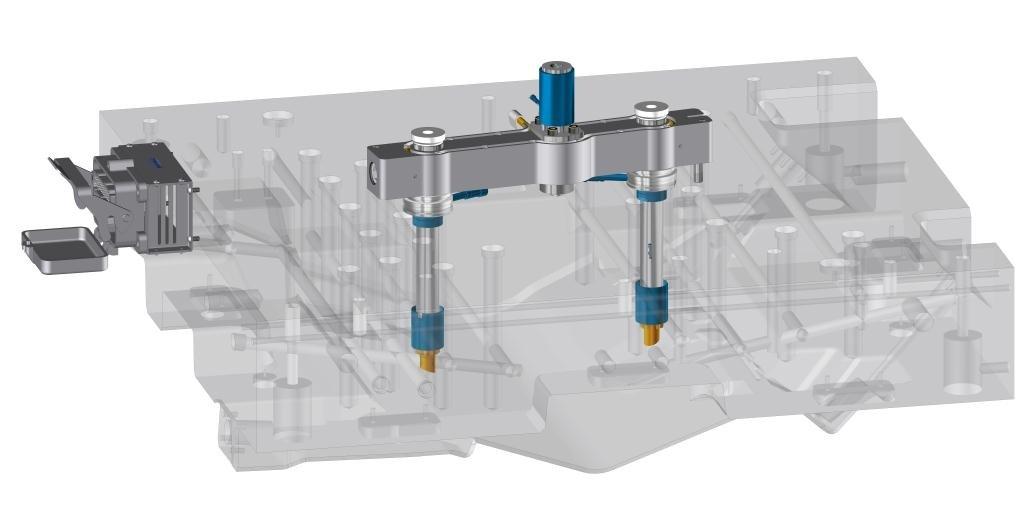

Perfect Balance +

Name of the part: Fan Grill

Material: PP

Weight: 662 g

Cavities: 2

Injection Points: 12

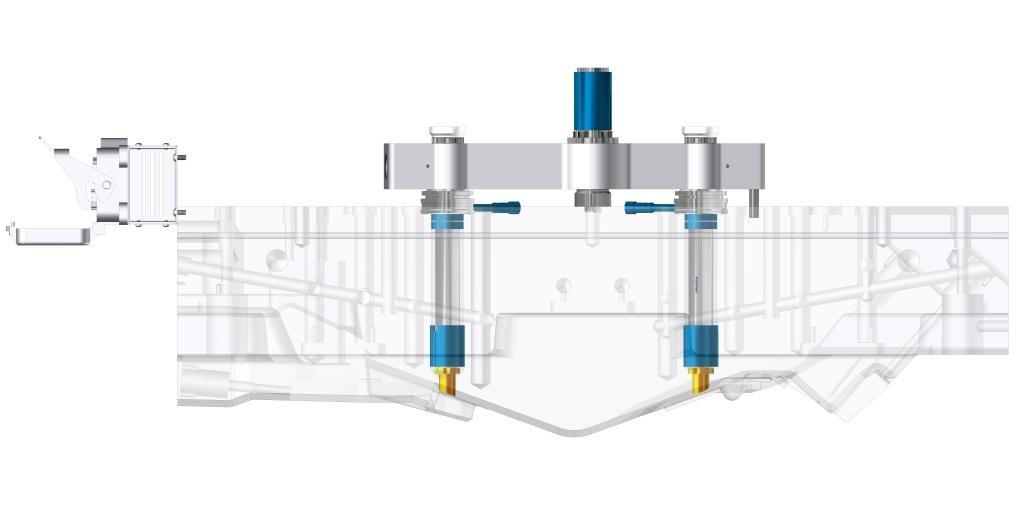

Injection: Standard Hot Runner System – Bridge Model

Serie: 500

Line: Policosmetic

Polimold Solution: Our client’s request had a very complex location for the injection points. The main goal was to develop a system that allows the uniform filling of the cavities, keeping the internal balance of the manifold’s FLOW CHANNELS.

We created a manifold splitted in the sections, two of them with six injection points (each) and above these ones a manifold linking these sections.

By using this layout, not only we established a perfect balance for the cavities, but also avoided an excessive thermal expansion of the manifold, which would cause the rupture of the threaded nozzles.